Standard EN 388 specifies the requirements for gloves designed to protect against the mechanical risks of abrasion, blade cuts, tears, puncture, and if applicable, impact.

Product performance is determined by the number of rubs required to deteriorate the product. For this purpose, an abrasive material is moved in a circular motion over the product, at a pressure of 9.0kPa.

There are 4 levels for this test (level 4 being the highest).

| Test | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Abrasion (6.1) | 100 | 500 | 2 000 | 8 000 | _ |

For this test, a circular rotating blade is moved over the specimen (from right to left) with an alternating motion and a constant force of 5N. The aim is to measure the number of rotations required to cut the product. There are 5 levels for this test (level 5 being the highest).

| Test | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Blade cut (6.2) | 1.2 | 2.5 | 5.0 | 10.00 | 20.0 |

Unlike the blade cut test, this test uses a straight blade. It is drawn across the surface of the product with a predefined contact force. This force varies between 2N and 30N. The aim is to determine the force required to make a 20mm cut in the product. There are 6 levels for this test (level 6 being the highest).

| Test | Level A | Level B | Level C | Level D | Level E | Level F |

|---|---|---|---|---|---|---|

| Blade cut (6.3) | 2 | 5 | 10 | 15 | 22 | 30 |

Tear resistance is defined as the force required to fully tear a rectangular specimen, which has been pre-cut, in a longitudinal direction for 50mm. The maximum force is 75N and corresponds to level 4:

| Test | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Tear (6.4) | 10 | 25 | 50 | 75 | _ |

There is no correlation between blade cut resistance as per standard EN 388 6.2 and cut resistance as per standard EN 388 6.3.

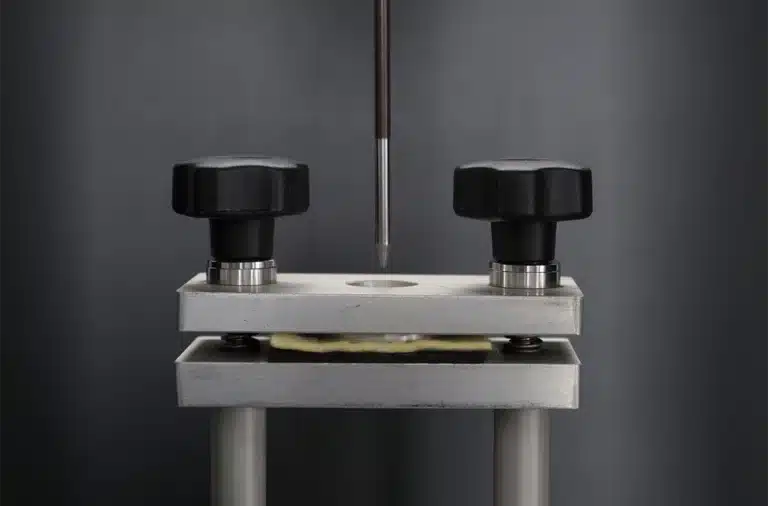

Test performed in our laboratory.

Puncture resistance is defined as the force required for a steel stylus to puncture the specimen. The maximum force is 150N and corresponds to level 4:

| Test | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|

| Perforation (6.5) | 20 | 60 | 100 | 150 | _ |

Test performed in our laboratory.