Standard EN 407 specifies the requirements to be satisfied for gloves or other hand protection against heat and/or flame in one or more of the following forms: limited flame, contact heat, convective heat, radiant heat, small or large splashes of molten metal.

Our far-reaching lab work and extensive testing simplify your certification procedures, by saving time and improving reliability.

This test is used to evaluate the material’s flammability resistance. To do so, it is exposed to a flame for 10 seconds and its performance is defined using the after-flame and after-glow times.

There are 4 performance levels for this test, level 4 being the highest.

| Performance levels | After-flame time (s) | After-glow time (s) |

|---|---|---|

| 1 | ≤ 15 | no requirement |

| 2 | ≤ 10 | ≤ 120 |

| 3 | ≤ 3 | ≤ 25 |

| 4 | ≤ 2 | ≤ 5 |

Test performed in our laboratory.

For this test, the material is placed on a heating cylinder and the time taken for the temperature of the material to rise by 10°C is measured. This test is carried out at different temperatures, ranging from 100°C (level 1) to 500°C (level 4), the time taken for the temperature to rise must be 15 seconds or more:

| Performance levels | Contact temperature Tc (°C) | Threshold time tt (s) |

|---|---|---|

| 1 | 100 | ≥ 15 |

| 2 | 250 | ≥ 15 |

| 3 | 350 | ≥ 15 |

| 4 | 500 | ≥ 15 |

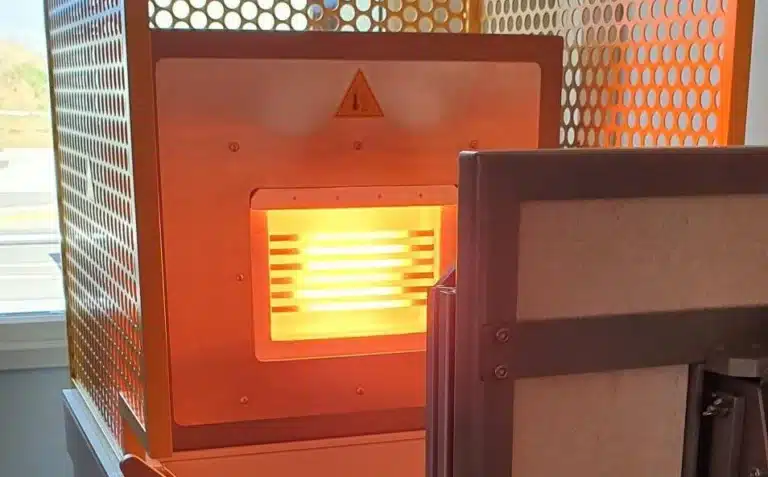

The bottom layer of the product is exposed to a flame of 80 KW/m². The objective of this test is to determine the time taken for the temperature of the top layer of the product to rise to 24°C.

There are 4 performance levels for this test (level 4 being the highest).

| Performance levels | Heat transfert index HTI (s) |

|---|---|

| 1 | ≥ 4 |

| 2 | ≥ 7 |

| 3 | ≥ 10 |

| 4 | ≥ 18 |

A specimen is exposed to a radiant heat source of 20kW/m² and the time required for its temperature to rise by 24°C is measured.

There are 4 levels for this test (level 4 being the highest).

| Performance levels | Heat transfert T24 (s) |

|---|---|

| 1 | ≥ 7 |

| 2 | ≥ 20 |

| 3 | ≥ 50 |

| 4 | ≥ 95 |

Test performed in our laboratory.

The aim of this test is to determine the number of molten metal drops required to raise the temperature of the material by 40°C without damaging the product’s different layers (no fusion occurs and inner layer free of holes).

Four levels are used to evaluate the material’s performance (level 4 being the highest).

| Performance levels | Number of drops |

|---|---|

| 1 | ≥ 10 |

| 2 | ≥ 15 |

| 3 | ≥ 25 |

| 4 | ≥ 35 |

The material’s resistance is evaluated according to the weight of molten iron required to cause superficial burning. Moreover, the metal drops must not adhere to the material and it must not ignite. Four levels are used to evaluate the material’s performance, the highest level (level 4) corresponds to 200g of molten iron.

| Performance levels | Molten iron (g) |

|---|---|

| 1 | 30 |

| 2 | 60 |

| 3 | 120 |

| 4 | 200 |