This international standard applies to clothing that protects the wearer against exposure to radiant, convective heat, or exposure to molten metal splashes (aluminium or iron).

It specifies performance requirements for clothing used to protect the body – excluding the hands, feet and head – against heat and flame.

Product performance is determined according to its behaviour when exposed to heat and flame in the following tests.

Our far-reaching lab work and extensive testing simplify your certification procedures, by saving time and improving reliability.

All materials in the structure of the clothing must be tested for limited flame spread and achieve index 3.

A specimen is exposed to a flame for 10 seconds and its performance level is defined in accordance with the following requirements:

| Properties | Requirements |

|---|---|

| Flame spread | Flame should not reach the edges of the specimen |

| Flaming debris | No flaming or molten debris |

| Hole formation | No holes ≥ 5mm |

| After-glow | After-glow time ≤ 2s |

| After-flame | After-flame time ≤ 2s |

Test performed in our laboratory.

The bottom layer of the product is exposed to a flame of 80 KW/m². The objective of this test is to determine the time taken for the temperature of the top layer of the product to rise to 24°C. The longer the time, the better the product performance, thus giving the wearer time to react.

There are 3 levels for this test (level B3 being the highest):

| Performance levels | Heat transfert index HTI (s) | |

|---|---|---|

| min | max | |

| B1 | 4,0 | < 10,0 |

| B2 | 10,0 | < 20,0 |

| B3 | 20,0 | |

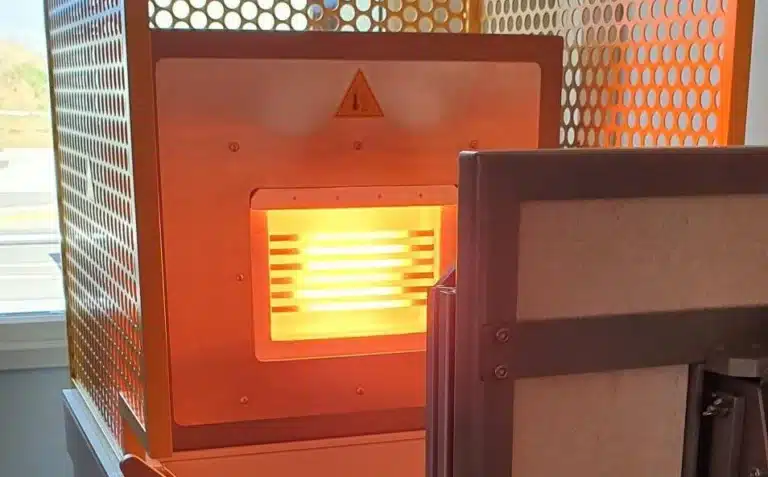

A specimen is exposed to a radiant heat source of between 20kW/m² and 40kW/m² and the time taken for the temperature to rise by 24°C is measured.

The longer the time, the better the product performance, thus giving the wearer time to react.

There are 4 levels for this test (level C4 being the highest).

| Performance levels | Heat transfert index RHTI 24 (s) | |

|---|---|---|

| min | max | |

| C1 | 7,0 | < 20,0 |

| C2 | 20,0 | < 50,0 |

| C3 | 50,0 | < 95,0 |

| C4 | 95,0 | |

Test performed in our laboratory.

For this test, the material is placed on a PVC film before molten aluminium is poured onto it. There are 3 levels for this test, corresponding to weights of 100 to 350g. If the material remains undamaged by 350g of aluminium, it achieves the highest performance level, i.e. level D3.

| Performance levels | Molten aluminium spashes (g) | |

|---|---|---|

| min | max | |

| D1 | 100 | < 200 |

| D2 | 200 | < 350 |

| D3 | 350 | |

This test is carried out in the same way as the molten aluminium test, the difference lies in the amount of molten iron used. The weight of iron used varies from 60 to 200g.

There are 3 levels for this test, level E3 being the highest:

| Performance levels | Molten iron splashes (g) | |

|---|---|---|

| min | max | |

| E1 | 60 | < 120 |

| E2 | 120 | < 200 |

| E3 | 200 | |

For this test, the material is placed on a cylinder heated to 250°C and the time taken for the temperature of the material to rise by 10°C is measured.

There are 3 levels for this test, level F3 is the highest and corresponds to a time of 15 seconds:

| Performance levels | Threshold time (s) | |

|---|---|---|

| min | max | |

| F1 | 5,0 | < 10,0 |

| F2 | 10,0 | < 15,0 |

| F3 | 15,0 | |

2022 ©Duflot industrie – All rights reserved I Legal notices I Conditions of use I Personal data I Created by: VANO créations